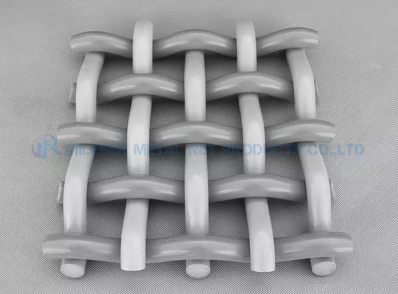

Properties and Benefits of Stainless Steel Woven Mesh

Stainless steel woven mesh offers a wide range of properties and benefits that make it a popular choice in various industries. Here are some key features and advantages of using stainless steel woven mesh: 1. Durability and Strength: Stainless steel woven mesh is known for its exceptional strength and durability. The interwoven and clinched design of the mesh ensures that it retains its structural integrity even when subjected to impact and other stresses. This makes it a reliable and long-lasting material for various applications. 2. Corrosion Resistance: One of the main advantages of stainless steel is its resistance to corrosion. Stainless steel woven mesh contains chromium and nickel, which provide excellent corrosion resistance, making it suitable for use in harsh and corrosive environments. This property ensures that the mesh remains intact and functional even in challenging conditions. 3. Versatility: Stainless steel woven mesh is highly versatile and can be used in a wide ...